Description

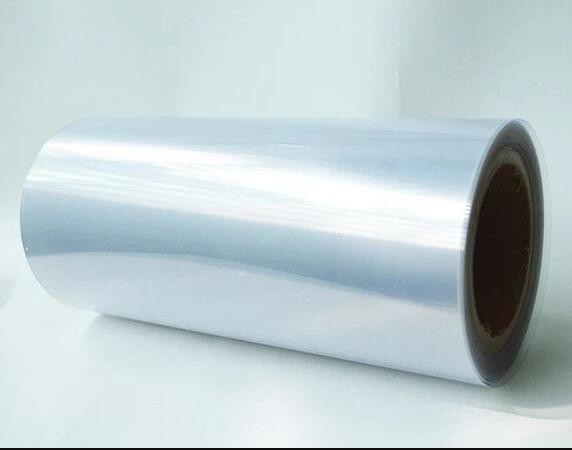

PVDC Sheet is a composite material made of copolymers of polyvinyl chloride (PVC) and chlorinated polyvinyl chloride (PVDC). It is transparent or translucent and has a smooth and uniform surface. The thickness of the film is usually between 20μm and 100μm, with high structural stability and no obvious surface defects. The surface of PVDC Sheet can be specially treated, and it is usually stretched and heat treated during the production process to ensure its physical properties and dimensional stability.

Features

Precise copolymer structure

The core advantage of PVDC Sheet lies in its copolymerized molecular structure. The copolymerization reaction of PVDC (polyvinyl chloride copolymer) and PVC (polyvinyl chloride) makes the film have a uniform molecular arrangement at the microscopic level. This structure gives PVDC Sheet a high degree of compactness and stability. Compared with a single polymer, the copolymer structure of PVDC can effectively enhance the comprehensive performance of the film, especially in terms of barrier properties and chemical resistance, reducing the gaps between molecules and improving the sealing of the material.

Compactness of polymer chain arrangement

PVDC Sheet is stretched and oriented during the production process, and the molecular chains are arranged more tightly. This dense structure makes the film inhibit the penetration of external substances and can isolate the penetration of gas, water vapor and other small molecules. Through the stretching process, the molecular chains of the film are straightened, which further improves the strength and rigidity of the film, while ensuring the uniformity of the film layer, which not only maintains the overall structural stability of the film, but also provides the film with better mechanical tensile strength.

Diversity of structural levels

PVDC Sheet can not only be a single-layer film, but also can be combined with other materials through co-extrusion technology to form a multi-layer composite structure. The combination of different levels can enhance its functionality. For example, by adding a protective layer or an anti-ultraviolet layer to the outer layer of PVDC, the durability of the film in complex environments can be further improved. The design of the multi-layer structure can not only improve the functionality of the material, but also optimize the balance between cost and performance, making it more adaptable in practical applications

Nano-scale surface treatment technology

PVDC Sheet uses advanced nano-scale surface treatment technology in the production process, which can improve the adhesion and sliding properties of the film surface. The surface treatment makes the surface of PVDC Sheet present a more delicate texture and reduces the generation of surface defects and irregular textures. This fine surface feature not only provides better adaptability for subsequent printing processes, but also establishes stronger adhesion between the coating and the membrane material, ensuring the stability and durability of the ink on the membrane surface.

Hot Tags: pvdc sheet, China pvdc sheet manufacturers, suppliers, factory, Moisture proof EVA interior decoration protective film, Pharmaceutical capsules tablet granule packaging aluminum foil, good airtight aluminum foil, waterproof Sheet film, good light blocking performance film, small roll wrap film